-

Scaife Hall Farm

- The Historic Landscape |

- Introduction |

- The Iron Bloomery |

- The Medieval Mills |

- West House Mill |

- The flax mill |

-

The flax process

- Child labour and the Apprentice houses |

- The silk mill and Westhouse Villas |

-

Scaife Hall Farm

- Leeds Corporation and Scaife Hall |

- Colonel Galloway, cricket and the 'Googly'* |

- Conclusion |

-

Historic Environment information

(Notes) | - Bibliography |

- Acknowledgements

Scaife Hall Farm

The Historic Landscape

Introduction

Blubberhouses cricket pitch - now the epitome of English Sunday afternoons and countryside tranquillity - but two centuries ago it would have echoed with the hustle and bustle of a five storey flax mill. This mill provided the central focus of a whole community of workers, many of whom were just children, and most of those had been gathered from urban workhouses. The following narrative will concentrate on the area in and around Scaife Hall Farm, and try to put it into its historical context, both locally and nationally. Alongside history, archaeology also provides clues to the industrial past, long before the establishment of the farm or the mill.

In order to understand the development of the mill and why it was built here, it is necessary to look back to the fifteenth century and the construction of a corn mill. The site must have been perfectly suited to making the most of the water power available in the River Washburn, so that by the end of the eighteenth century a large linen mill was established. The story of this mill is one of 'boom and bust', as three different owners lavished money upon it, extending and modernising it, but all ultimately ending in bankruptcy. Its end was abrupt – bought and demolished by the Leeds Corporation Waterworks, with its stone being used to build a wall around Fewston Reservoir.

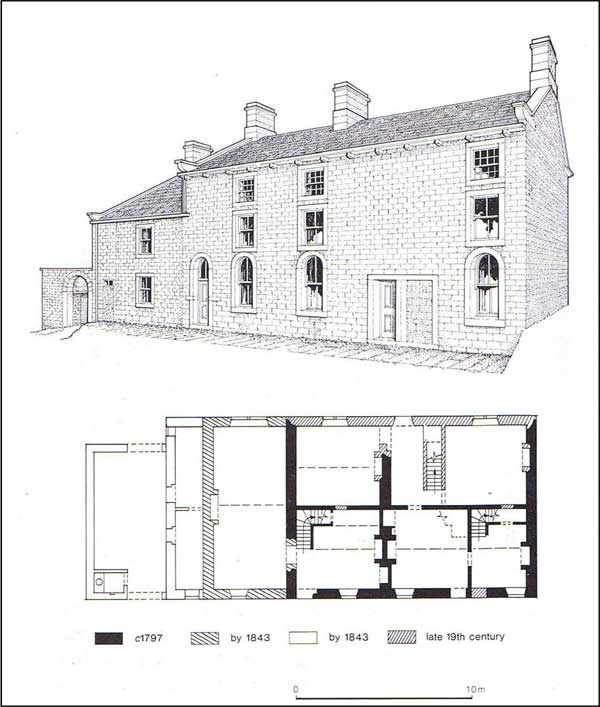

The farm itself appears to be as much a product of the Industrial Revolution as West House Mill. Built in the early part of the nineteenth century, the layout of the farm, its animal accommodation and the ornamentalisation of its fields show the distinct hallmarks of the model farms of the 'Age of Improvement'. The farm was probably built around the turn of the nineteenth century; at the same time as the flax mill. This was during the Enclosure Acts, when much common grazing was parcelled up into fields.

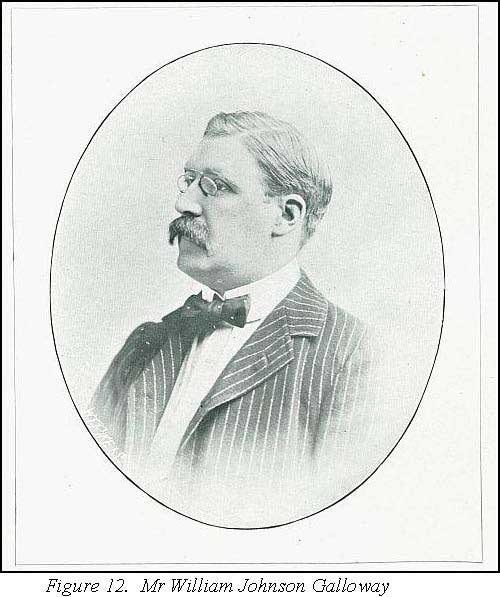

During the early nineteenth century, the mill owners built a prestigious residence close to the mill, which was to become Scaife Hall. By the end of the 1800's, Colonel William Johnson Galloway, MP in Manchester, took the Hall as his country residence, and through his passion for cricket, he established the ground for Blubberhouses Cricket Club.

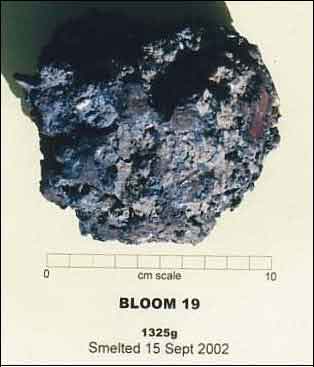

The Iron Bloomery

A large mound of iron slag remains, in the corner of one field to the north-east of the farm, reveals that during the medieval period this area was already a hub of industry. Large amounts of iron slag indicates to the archaeologist that this area would have been the site of an iron bloomery; where ironstone was smelted.

Documentary evidence also points towards a bloomery in this area from the thirteenth century onwards. The land-owner, John, son of John de Walkingham, is recorded as giving leave to the Canons of Bridlington to dig iron and make forges in the vicinity of Blubberhouses during the 1200's (Grainge, 1871; 501). The local history society have also found records, the first of which mentions an iron forge at Blubberhouses dating to 1227, and then a lease of an ironworks to Adam Fox and partners in 1284-5. Interestingly, Blubberhouses may have derived its name from the 'blowers' or 'blauers', which was the local name for the iron-smelting furnaces, that were abundant around here.

Iron bloomeries of this period were basic, with a clay lined pit being charged with charcoal that was heated up with hand bellows until it was white-hot. Ironstone and charcoal were then added in equal quantities, and the molten slag was tapped. The end product was a spongy mass, as the bloomeries did not operate at sufficiently high temperatures to produce a pure iron (see figure 1 below). Although water-driven bellows became common in the medieval period, and this bloomery is situated close to a stream, its date would suggest that the bellows were probably operated by hand. Archaeological evidence has shown that by the thirteenth century, water power was just coming into use in Europe and had not yet reached Britain.

Figure 1. This bloom was produced using experimental archaeology and gives a good idea of the finished product made in a medieval bloomery

The Medieval Mills

It is known that a fulling mill existed on the site from the sixteenth century, when Robert Ward was given a licence to build a mill in the Washburn Valley in 1526. Fulling was a process in which wool was washed and pounded, so that the end-product was a smooth, felt-like cloth. Wool was a key part of the local economy by this time, at least until the 1550's when the export trade collapsed. Some fulling mills closed, and the mill at West Houses was ultimately replaced by a corn mill. Although it is not known exactly when it was built, the mill was still in operation until the 1840's in tandem with the later linen mill.

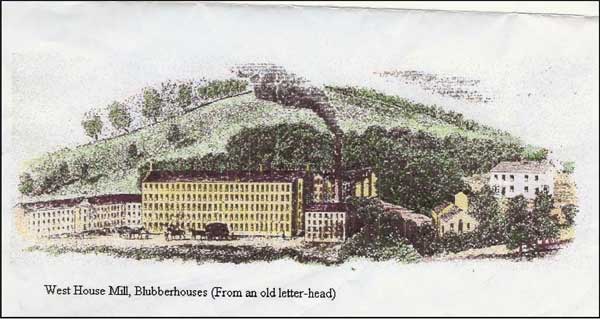

West House Mill

Figure 2. West House Mill in its heyday, with Westhouse Villas (Scaife Hall) on the right

The flax mill

The building of the first West House flax mill in 1797 reflected the growing importance of the flax and linen industry within Yorkshire during the 1700's. Amazingly, for such a widespread industry throughout the county, the production of flax and linen was confined to at best only five percent of the total textile production, with many mills concentrating upon wool and worsted production. Linen manufacture was to reduce significantly after succumbing to competition from cheap cotton in the later part of the nineteenth century. By the late eighteenth century, the area around Nidderdale, Pateley Bridge and the Washburn Valley was a focus of activity as the numbers of flax mills increased. Meanwhile, close by in Knaresborough, linen-weaving provided many with a source of employment. From the late eighteenth century the technology was in place to produce flax and linen on a mass scale, as mechanisation replaced some of the more laborious hand methods. No doubt West House Mill made the most of all this new technology.

The flax process

Flax had to undergo a lengthy process to produce suitable fibres for weaving. First, the plant fibres had to be separated from the rest of the plant by retting and scutching; the plant was left to soak in water until the softer parts had decomposed, and after it was dried and beaten until only the fibres remained. Much of the flax used in the Yorkshire mills was imported from Holland and Russia, via the port at Hull and often arrived already scutched. Before it could be spun, the flax fibres had to be straightened out and untangled by carding, which became mechanised after 1775. Short and long fibres were derived from flax, and they were spun separately, with the shorter tow being used for coarser products and many household linens being derived from the longer line. Flax spinning was mechanised by 1787, and the scene was then set for a massive expansion of the linen industry.

Figure 3. The interior of the flax mill Marshalls at Leeds; of similar size to West House Mill.

It was only ten years later in 1797 that West House Mill was built. The mill took advantage of the new mechanisation plus the good water flow from the River Washburn which was to supply energy for the machines. The original owners, Colbeck and Holdsworth, had to raise a mortgage of £2,400 for the mill and land, but it is not known how deep they had to dig into their own pockets. They were joined by Wilks, a linen manufacturer, and Ellis, a co-owner of Wreaks Mill, within a few years of starting the business. It was in 1807, encouraged by Wilks, that West House became fully integrated, manufacturing linen as well as flax, in the purpose-built weaving factory situated to the rear of the mill.

As the mill was now producing linen, the bleach fields which lie behind the cricket pitch on the fields of Scaife Hall Farm would have been created. The most desirable linen was of course pure white. This was achieved by soaking the cloth in alkali and laying it out in the sun, it was then 'soured' in buttermilk before being washed. Although successful, this method could take up to eight months to complete, and consequently was not really commercially viable. By the first half of the nineteenth century, this had been replaced by using chlorines and then sulphuric acid for souring. This process was completed in a fraction of the time and at this piont the bleachfields probably became redundant.

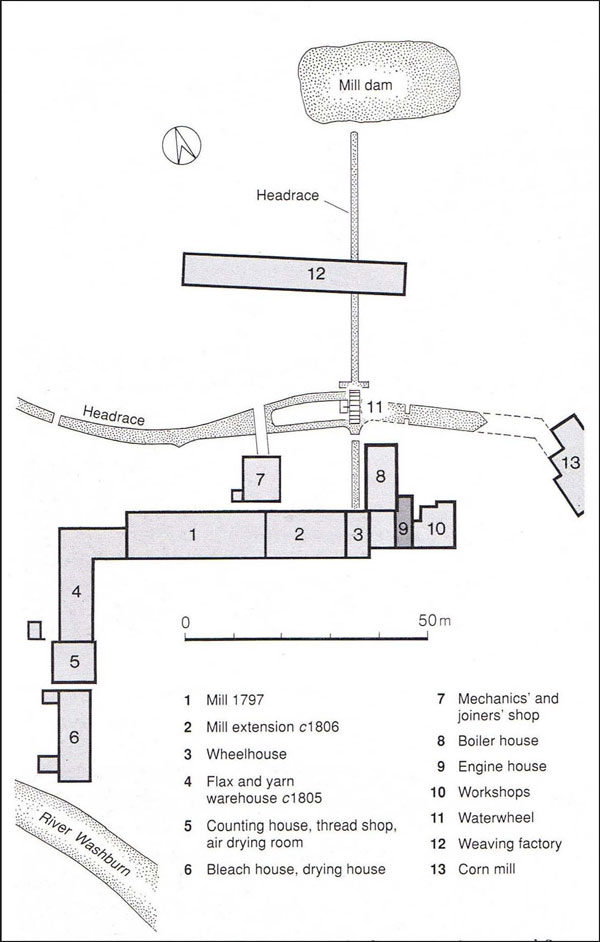

The fact that West House Mill was spinning and weaving was very unusual, considering that during the nineteenth century only five percent of all Yorkshire mills were flax mills, and of these only a handful were integrated. The insurance policy details (below) give a good indication of the size and complexity which West House Mill reached once it was flax spinning and weaving.

1816 Insurance Policy Details for West House Mill included;

Flax and yarn warehouse Two flax mills with carding and breaking engines Engine and boiler houses Workshop Weaving factory Counting house Thread shop Air drying room Bleaching and drying houses Houses Cottages Two apprentice houses

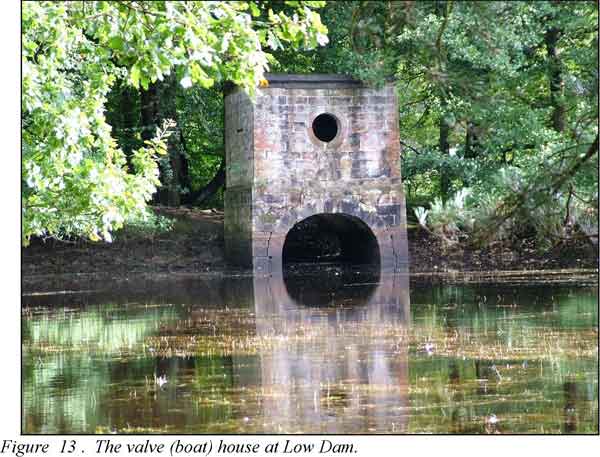

Although water power was cheap to produce, the vast engineering project undertaken to build Low Dam and the mill race was very expensive for the time. The embankment of the mill race, the neat stonewalls, ornamental bridge (see figure 4 below) and valve house are all testament to the investment required to run the mill. Usually water had to be taken from a nearby stream or river by means of an artificial channel, or headrace, which led to the water wheel at the mill. To ensure a good supply of water dams were built so that the mill could work even in times of drought. The large Low Dam was required to provide enough water storage to keep the mill's only power supply running. The mill-race was not just functional. Along one side of the bank where the footpath currently runs, there was probably a promenade integrated into the mill race, as the remains of iron railings can still be seen (see figure 5, below). This could have added to the parkland feel of the mill and the farm, while providing a chance to appreciate the landscape.

Figure 4. The ornamental bridge over the mill race – note the curved coping stones on the far wall

Figure 5. The line of iron railing footings can be seen running along the right side of the path. Inset is detail of a footing.

Even though the economic depression in the early eighteenth century was without doubt significant in the closure of the mill, it is possible that the extra debt incurred during its extension may have aided its downfall. It may also help to explain why, by the time that the company had gone bankrupt in 1816, not a penny had been paid on the mortgage. Between 1813 and 1814, the owners built a new dam, High Dam, and a subterranean culvert which led to a new overshot water wheel. At the time of their bankruptcy, their debts had risen to nearly £12,000, which had to be paid by the next owners, Chippendale, Netherwood and Carr who took over in 1820.

Michael Robinson – local boy made good

A son of the local blacksmith, it was said that Michael Robinson could not wield the hammer, and so had to concentrate upon his studies. He must have done well, for when the owners of the mill wanted to extend and build a new water wheel, they employed Michael as their engineer. Only in his twenties, Michael built High Dam and oversaw the construction of the stone culvert down to the new wheel. It was a feat of engineering appreciated by the owners, who kept him on after the work was completed. After Colbeck and Wilks went bankrupt, Michael stepped into the breach and became manager of the mill for the next owners. It was Michael who managed the mill through the boom of the 1830s, and, who also made sure that the workers were paid above average so that they would stay with the company.

Chippendale and partners reaped the benefits of all the previous investment, for a time at least, while adding their own improvements. Further extensions were built to include a heated dryhouse, new warehouse and bleachworks. The engine house (9) still stands today at one side of the cricket pitch and houses an old turbine (see figure 6, below). During the early 1830s, business was booming and by 1836, £3000 had been paid off the mortgage! In the same year the sons of Netherwood and Carr bought the mill, which then came under the sole ownership of Netherwood by 1839. Perhaps Carr knew something Netherwood did not, as the downturn in trade continued and by July 1844 Netherwood was a ruined man with debts totalling over £37,000.

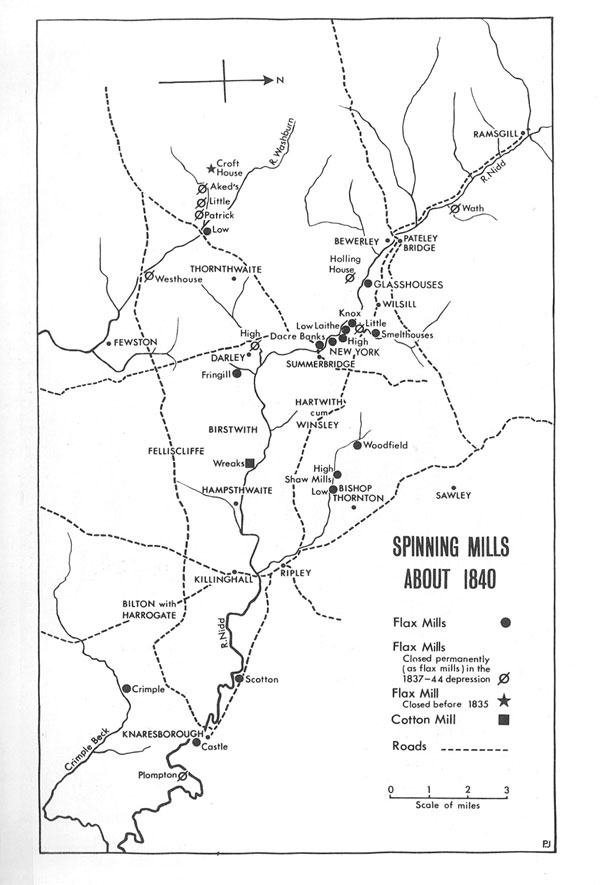

Figure 6. Plan of West House mill

Why did these slumps occur? Firstly there was a general deterioration in the economy in the late 1830's, and secondly the more remote mills in the Washburn Valley were hit by the competition. The mills of Nidderdale and, especially Leeds, were now producing vast quantities of linen in much more accessible locations, plus the demand for linen had decreased as cheap cotton had come onto the market. To add to their difficulties, France, their major importer, had levied such high tariffs on the yarn that it it had become too expensive for the French to buy. The days of West House Flax and Linen Mill were now over, until another use was found for it.

Figure 7. Map of spinning mills in Nidderdale circa 1840, showing which mills had closed.

Child labour and the Apprentice houses.

Figure 8. Child mill-worker.

Being so remote, the mill expanded so quickly that it soon exhausted the supply of local labour. The first owners, Colbeck and Holdsworth, began to visit the workhouses of London and other cities, to bring back pauper children as young as nine to be employed as apprentices. The worst job of all was reserved strictly for children called “doffers”. For up to thirteen hours a day they had to attend to the relentless spinning machines, taking off the full bobbins and replacing them with empty ones. With only an hour's break a day, the continual labour resulted in 'postural deformities' which at the time appalled Charles Thackrah so much so that he became a contributor to the Factory Act of 1933. (Charles Thackrah was the founder of modern day occupational medicine.) This Act ensured that children between the ages of 9 and 12 years were only allowed to work 48 hours a week with compulsory time-off for education. And the older children? They had their time cut to 69 hours a week with no night shifts! I cannot help but wonder if their wages were cut accordingly...

Fortunately a first-hand account of life and work at the mill survives; written by Robert Collyer, who went on to become a Unitarian minister in North America. He describes the long, hard days of labour when corporal punishment was never far away.

“...rung in at six in the morning and out at eight in the evening, with an hour for dinner and a rest. And, if we got a chance to sit down for a few moments when the overlooker was not round with his leathern strap to lay on our small shoulders, we were in link, while for protection we invented a code of signals to warn each other when he was coming our way; and the result of this was that the weaker children were so crippled... The quite infernal factory bell began to clang through the valley at half past five in the morning, before, as I was sure, I had been asleep an hour, so tired I was and so sure also that in all the world there could be no bell so harsh or evil in sound.”

(Pateley Bridge Local History Tutorial Class, 1983, A History of Nidderdale, pp.222-3.)

If the threat of the strap was not enough, the children had to be constantly aware of the dangers of the mill machinery. Inevitably, many factory workers were involved in accidents probably from a combination of tiredness and unguarded machines, which could result in serious injury. The most common were to the hands and arms which could get easily caught in the machines and sometimes resulted in the loss of fingers. Far more common were deleterious effects on the lungs caused by flax dust, the effects of which are now known as 'byssinosis'; an ailment which causes breathlessness and tightness of the chest.

After a time, these children grew up and had their own families, producing another generation of mill-workers for the factory owners, so workhouse children were no longer needed. In fact, both Robert Collyer's parents had been pauper apprentices at the mill. Employing pauper labour was not a cheap option at West House, as the children had to be housed, clothed, fed and educated. The children were housed in High Apprentice House, for boys, and in Low Apprentice House, for girls. High Apprentice House was probably built at the same time as the flax mill to provide accommodation for mill-workers, but was soon converted for the children. A Workhouse was also in existence on Hardisty Hill, and presumably provided adult labour for the mill. With the influx of population came the expansion of Methodism into the Washburn Valley, and West House Mill was recorded as having its own society by the first part of the nineteenth century.

Figure 9. The Apprentice Houses

The silk mill and Westhouse Villas

Between 1844 and 1858, West House Mill stood empty, and with no employment the labour force had to move on. In 1841, the population of Fewston parish was 850, but this had fallen to 399 by 1851. Times were hard, as the Poor Law had changed in 1834, so those requiring relief were no longer able to fall on their parish. Instead groups of parishes called Poor Law Unions had come into existence, and the destitute were sent to the Workhouse.

By 1858, however, the future began to look more promising, as West House Mill was bought by Crowthers of Halifax and reopened as a silk mill. This was a much smaller enterprise than previously, which is well demonstrated by the number of workers recorded as 31 in the census of 1861, in comparison to 200 in the flax mill in 1836. It is probably about this time that a gas apparatus was installed to provide lighting at the mill. Even this small textile business could not be maintained, perhaps due to a lack of local skilled labour, the remote location of the mill or stronger competition elsewhere, and it closed by 1864. It seemed to be the same old story; the owners were left with large debts of nearly £6,000 and the labour force had to move on.

The mill was purchased by the Leeds Corporation, who were building vast reservoirs in the area, to supply drinking water to the city of Leeds. The mill was subsequently demolished, however the grand mill-owners' house, West House Villas, was turned into Scaife Hall. West House Villas was probably built by the original owners of the mill, and was then extended and refurbished by later owners. It was not unusual for the owners to live close to their mill, and especially in more luxury than their workers. A distinguished residence confirmed their place near the top of the (local) social order, and helped to give the impression that all was well with their business.

Scaife Hall Farm

During the 1770's, potential and existing farming land in the Forest of Knaresborough was subject to extensive parliamentary enclosure. The end result was the division of the very large open fields of medieval origin, (usually shared between an agricultural community) and the previous 'waste' grounds. This produced a vast social and economic change as ownership and access to any piece of enclosed land was through an individual owner. The period of enclosure also coincides with the 'Age of Improvement' in the late eighteenth century; a time when the application of science and reason became popular in agriculture. As the urban populations grew, agriculture had to become more productive especially in terms of 'high output/low input'. Cattle were selectively bred, and housed in the winter, which produced large amounts of manure for the fields. Model or planned farms were built accordingly, often based around a courtyard, with ornate cowsheds, and some ornamental plantings in the fields. At Scaife Hall Farm, the architectural style, especially that of the cowsheds with their large circular windows, is highly indicative of the model farm. Trees were also planted around the farm presumably to give it more of a parkland feel.

Originally the farm was known as “Skaife House Farm” until 1904, and formed part of the estate of West House Mill. After the flax mill had lain idle for three years, the estate was broken up and sold off at auction in 1847. The farm was bought by a John Gill, whose wife Jane was the Granddaughter of William Hardisty – the family which gave their name to Hardisty Hill. Matthew Gill, John's son, succeeded him and was the quarry owner at Hanging Moor. (His address given on his letterhead however, was 'Skaife House', which possibly was meant to sound grander than 'Skaife House Farm'.) The mill races, sluices and culverts which powered West House Mill ran over Gill's land, and during 1868, he wrote to the mill owner's solicitor asking for the waterways to be repaired. Matthew Gill died in 1895, leaving the farm to his seven children. Unfortunately their home was then compulsorily purchased by the Leeds Corporation in 1904.

Leeds Corporation and Scaife Hall

The water which had powered the mills of the Washburn, became an important commodity for the city of Leeds in the later part of the nineteenth century. As Leeds attracted more and more inhabitants, sanitation began to reach crisis point. By 1870, it was estimated that 30,000 privies were still in use as the take up for the connection of house drains to the mains, and therefore the connection of water closets was extremely slow. The middensteads (piles of dung) were still commonplace, and the threat to human health was escalating. During the 1870's, the Sanitation Committee began to target, what it termed as the 'abominable middenstead and cesspool' which was the streets of Leeds. To overcome this, the Leeds Corporation was given the task of water supply from the Washburn Valley down to the city.

The Leeds Corporation began work on the Fewston Reservoir in 1874; one of a group of reservoirs in the Washburn Valley. Fewston Mill was pulled down immediately, whereas West House Mill was given a reprieve until 1877, when it was demolished and the stone reused on the walls of the reservoir. Fewston Reservoir was opened officially in 1879, and had a capacity of 866 million gallons. Although the workers' cottages by Blubberhouses Bridge were pulled down, West House Villas were kept on by the Corporation, and became Scaife Hall. This was made into a residence fit for a gentleman, with ornamental gardens and ponds, and then let until the early twentieth century.

Colonel Galloway, cricket and the 'Googly'*

Scaife Hall was rented out to a Colonel Galloway, a gentlemen who was a Conservative MP for South-West Manchester. His rank as Colonel was honorary, and there is no mention of him serving in action. He was, however, a well-travelled man, whose father and uncle had patented the 'Galloway Boiler' used widely to produce heat and power in the mills. Colonel Galloway must have found Scaife Hall an ideal place to 'get away from it all' and indulge in the local cricket club. It could be said that Colonel Galloway was a product of his times. He was proud of his involvement with his mother's philanthropic mission in Hulme, yet at the same time was the first Honorary Secretary to the South African League. This was a highly political group who were pro-apartheid and anti-trade unions, with one of their main adversaries being the ANC.

Yet in other ways, Galloway was way ahead of his contemporaries. In 1902, he wrote a treatise entitled 'The Operatic Problem', in which he promoted the idea of a national opera which would be affordable for everyone, and not just the privileged few. (The English National Opera was formed in 1974.) The book is a long and complicated look at the organisation of music throughout Europe and beyond. It reveals an interesting side to Colonel Galloway, who was passionate about music and believed that it could cure all manner of social ills.

Galloway wrote; “I have never known a true lover of music who was not a good citizen. And what a preventive against idleness, the cause of so much crime ... produce opera at a price which all can afford to pay to hear, and can anyone doubt, that many a man and woman will choose it, in preference to an evening in a public-house or a music-hall. I never remember listening to an opera, however poor or badly performed, that I have not gained some strength with which to continue the desperate struggle of the battle of life which is very much more than I can say, for instance, for speeches in the House of Commons.” (Galloway, W.J., 1902, The Operatic Problem, p.

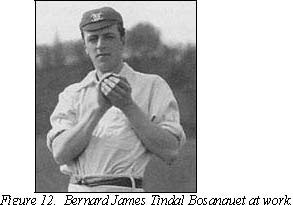

Colonel Galloway and his family were great supporters of the Blubberhouses Cricket Club. He improved the cricket ground and even built a bandstand to one side of the pavilion. The Colonel held an annual cricket festival, which helped the club to grow in stature so that it began to attract internationally famous players. One of the most notable cricket players to attend was B.J.T. Bosanquet (figure 12), the player who invented the 'googly', which caused a great deal of controversy during its time. (For the uninitiated - the Googly occurs when a cricket ball is bowled as if to break one way then actually breaks in the opposite direction.).The googly was deemed as cheating and even the leading batsmen of that era called for it to be banned. Bosanquet had apparently quipped that the Googly was 'not unfair chaps, just immoral'.

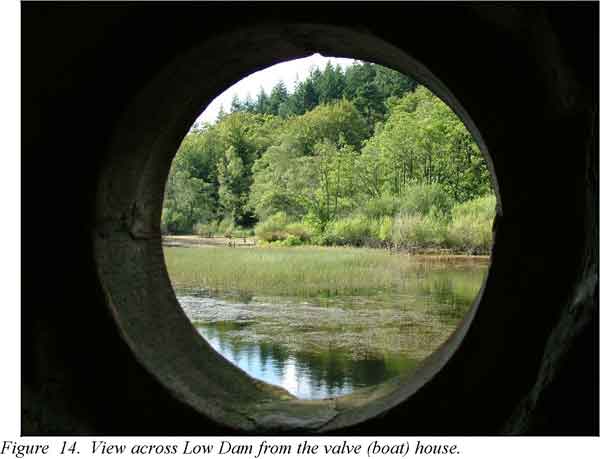

The impression given by William Galloway is of a man who enjoyed the finer things in life. His involvement with opera, cricket and the gentlemanly pursuit of rowing on Low Dam are all testament to this enjoyment. The valve house on Low Dam was even converted into a boat house for Galloway, so that he could enter his boat without having to get his feet wet (see figures 13 and 14, below).

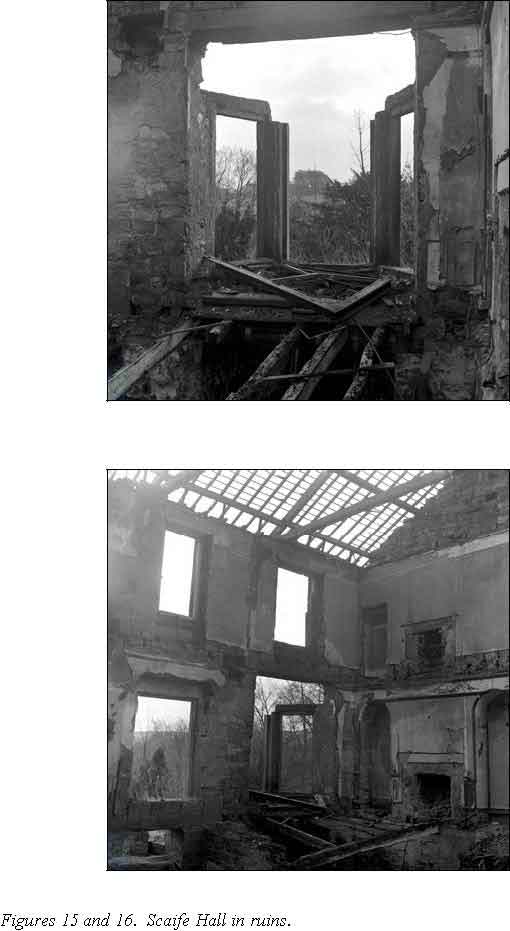

After Galloway left Scaife Hall in 1924, Leeds Corporation did not let the house again. It was left to gradually deteriorate until it was pulled down (see figures 15 and 16 below). Some remains still exist today, such as the ornamental gardens which are much overgrown, but still with beautiful exotic trees and well-built walls around the garden. The pond built by the Leeds Corporation can still be seen on satellite images.

Conclusion

In brief, the story of the mill may be one of boom and bust followed by total demolition, but enough remains for its importance to be appreciated still. The spectacular Low Dam and the long millrace are testimony to the huge human effort and ingenuity required to power the flax mill. The mill played its part both on the national and international stage, importing workers from the cities and flax from even further afield. In a time when globalisation was becoming increasingly important, the mill was also subject to the ebb and flow of trade throughout Europe and beyond. It seems almost ironic that eventually the owners' house and what was left of the industrialised countryside became the playground of a gentlemen whose money had come from mill boilers. Yet Galloway's love of cricket brings the story almost full circle, from flax spinning to the linseed used to oil the cricket bats – all completed in just over a century.

Historic Environment information (Notes)

The area of woodland between the cricket ground and the road to Hardisty Hill probably still contains a fair amount of information on the historic environment. In that area not only was there Scaife Hall, but also the ornamental gardens. The weaving shop appears to have been sited in that area, and there are possibly the foundations of workers' cottages still remaining. If any development is proposed for that area, an archaeological survey would be recommended, as its importance lies in its place within the wider context of the history of the landscape, especially as the mill itself appears to have been completely flattened. North Yorkshire County Council HER plus the Heritage and Environment Section would also need to be consulted fully.

The photographs above show a huge waterpump which is located in the northernmost bleachfield, I think that the inscription refers to Appleby & Co, Renishaw Ironworks, Renishaw, Derbs (between Chesterfield and Sheffield). Of which I have only found mention of a few other pumps similarly inscribed around the country at Graveley, Herts Wethersfield & Great Canfield, Essex and Todwick, Yorks.

On the web at http://myweb.tiscali.co.uk/pumps/manufs.htm The Renishaw History Group has reported that Appleby & Co Renishaw Iron Works were founded in the late 18 century by Thomas Appleby , who died on 15 Nov 1814. James Appleby, probably his son, is mentioned in 1841 as being the owner, and the Renishaw Iron Works was by the mid-19th Century one of the largest in Britain. It closed in 1999. If correct this may have been in place when the flax mill was first built.

Bibliography

Giles, C. and Goodhall I.H. (1992) Yorkshire Textile mills, The Buildings of the Yorkshire Textile Industry 1770-1930 , London, HMSO Royal Commission on the Historical Monuments of England and West Yorkshire Archaeology Service.

Grainge, W. (1871) The history and topography of Harrogate and the Forest of Knaresborough, Leeds, MTD Rigg Publications (1988 Edition).

The Pateley Bridge Local History Tutorial Class, (1983) A History of Nidderdale, edited by

B. Jennings, published by the Nidderdale History Group Pateley Bridge (second edition).

Figure 1 from Wealdon Iron Research Group,

http://www.wealdeniron.org.uk/Expt/bloom.htm, date unknown.

Figure 2 – from Blubberhouses Cricket club web page

Figure 3 -(Print collection Maggie Land Blanck )

Figure 8 Illustration from http://www.spartacus.schoolnet. co.uk/IRaccidents.htm)

Figures 15 and 16, The Unnetie Collection, 2003, these are copyright of North Yorkshire

County Council.

Acknowledgements

Much invaluable data was provided for this project by the North Yorkshire County Council Historic Environment Record. I would like to thank everyone who helped me during the project, and especially Paul Burgess, Marjorie Davy, Pippa Pemberton, Chris and Christine Ryder (Scaife Hall Farm), Linda Smith and Marian Whilby.

by Lynne Johnson